Low friction, non grip, anti-vibration u-bolts - the new and innovative 1111 Series

Introducing our brand new, patented, low friction, non-grip, anti-vibration u-bolts.

Graphskill’s new Series 1111 Ubolts

Protected by U.K Patent Number 2 557 288 - All Rights reserved

These ubolts have been developed to enable pipes to be securely guided with a minimum of friction so safe-guarding the pipe from expansion & contraction wear due to temperature changes; whilst also reducing the noise & vibration of the pipe.

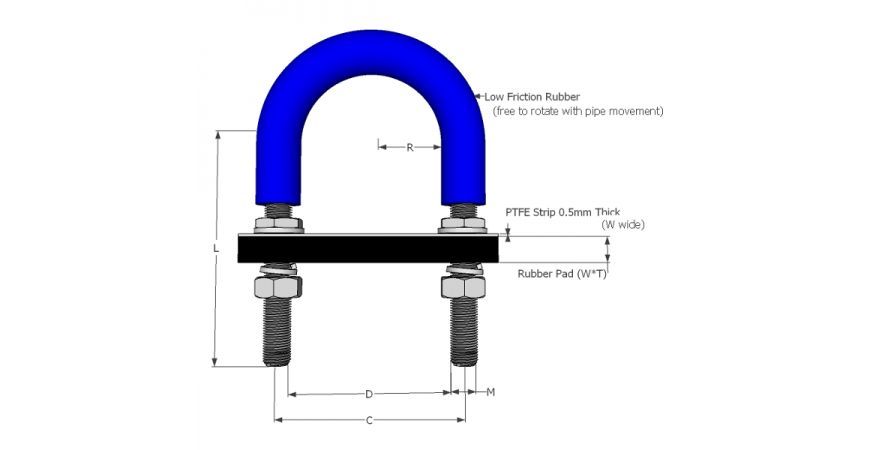

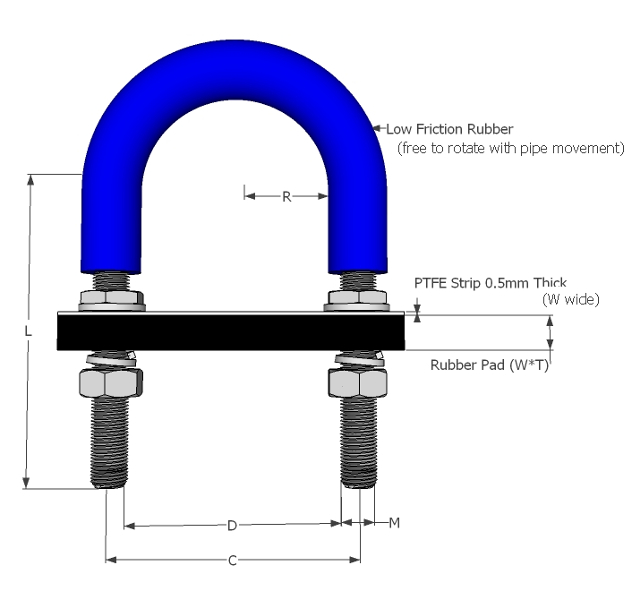

They are fitted with a gap between the ubolt and the pipe enabling the pipe to expand & contract yet keeping it fully guided in position.

The rubber base pad acts to reduce the noise & vibration of the pipes as they carry their fluid and it is fitted with a PTFE strip to reduce the friction and hence protects the pipe as it expands & contracts. The pad also contains a metal spacer for the U-bolt legs to go through giving strength to the pad and a firm anchor for fastening the nuts at the required position.

The patented ubolt sleeve is a low friction silicone rubber that rotates around the ubolt to enable the pipe to move unrestricted but be fully guided in position on the supporting framework.

These are a much cheaper and more reliable solution to the conventional rubber lined ubolts which have PTFE bonded to the inside surface of the rubber-coated ubolt.

Although Ubolts with the PTFE strip bonded to the rubber profile around the ubolts have been in common use for many years, they are prone to the PTFE separating from the rubber due to the difference in the expansion coefficient of the rubber and the PTFE. This problem is eliminated by Graphskill’s unique solution of a single medium with minimal friction

Check out our fantastic range: HERE