What is a pipe Saddle clamp and how do I measure them? Intruducing Graphskill SUMS!

Pipe Saddle clamps

Pipe saddle clamps are used to clamp a pipe to a flat surface – traditionally of two styles, grip type (anchor) or non-grip type (saddle/guide). The clamp will have two holes to allow fixing bolts to fasten the clamp to a wall, floor, wooden joist etc

Grip or Anchor clamp

Grip clamps, sometimes called anchor clamps are used when the pipe requires tight clamping to restrict all movements. You can see in the image below how there is no gap between the pipe and the inner surface of the clamp.

Grip / Anchor Style Pipe Clamp

Non-Grip or Saddle/guide clamp:

Non-Grip clamps, sometimes called guide clamps are used when it is desirable to have a looser fit to allow some movement. Movement could be thermal or mechanical (perhaps a vibration). Below is a representative image showing a gap between the pipe and the clamp. Realistically there would likely be some contact at the top surface.

Non-Grip [Saddle/Guide] Style Pipe Clamp

Traditionally pipe clamps were referenced by the size of the pipe they were clamping. So for example an engineer would ask for a pipe clamp for a 50 nominal bore pipe. No reference to the size of the clamp, thickness of the material, size of the holes etc.

Graphskill Sums

Graphskill Sums (GSUMS) is the new way of labelling pipe clamps

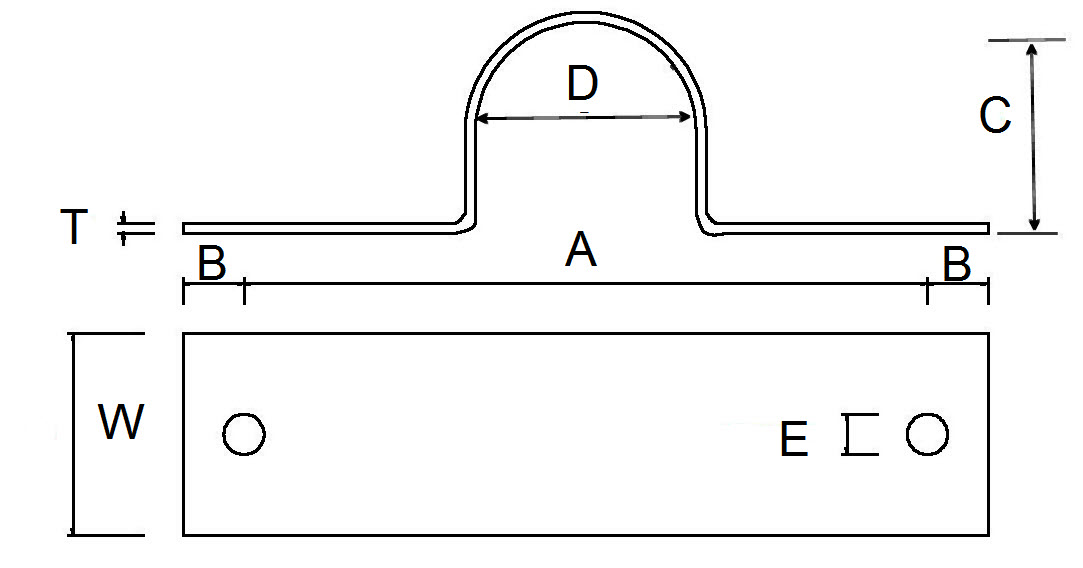

Pipe clamp drawing for Graphskill Sums

Inside Diameter=D

Inside height=C

Material Width=W

Material thickness=T

Hole centres=A

Hole centre to edge=B

Hole diameter=E

So the code for a pipe clamp becomes: Graphskill SUMS=CLAMP/MATL/D-W*T-C-A-B-E

Example: CLAMP/T304/64-40*8-63-140-30-14

This clearly defines the physical dimensions of the clamp. Grip or non-grip becomes meaningless as the engineer knows the outside diameter of the pipe. So for example, in the above example, if the outside diameter of the pipe is 63 mm, the engineer could ask for Inside Diameter=D = 64 as above, or if they wanted a non-grip style they could ask for Inside Diameter=D = 68 (or whatever clearance they require)

A word of Caution

The inside diameter of a clamp is very often less than the inside height and this can cause some confusion. The idea is that the clamp does NOT sit flush against the wall. Having less inside height means the saddle will sit proud on top of the pipe with a gap to the wall. Then as you tighten the fixing bolts the plate bends slightly towards the wall and so produces the clamping effect on the pipe. If the clamp fit flush to the wall as soon as you address it to the pipe, then it simply would not grip the pipe sufficiently.

Graphskill manufactures a wide range of anchor and guide clamps for British Standard Pipe sizes. In stainless steel, zinc plated and galvanised finishes. We also have some non-standard sizes, and of course, can manufacture bespoke clamps